IEC61131-3

For many years, the control systems market has seen the proliferation of a variety of programming languages and development environments, different for each manufacturer.

IEC 61131 standardizes the technology of programmable controllers and covers equipment requirements, programming languages, operating guidelines, communications and functional safety.

The third part of IEC 61131 (IEC 61131-3) deals with the programming languages used in programmable controllers, of which there are 5.

IEC 61131-3 defines a series of functions and data types that must be supported by all compliant PLCs. The functions are the building blocks of all programs and include arithmetic operations (addition, subtraction, etc.), Boolean logic (AND, OR, NOT, etc.) and programming structures such as loops, comparisons and decisions.

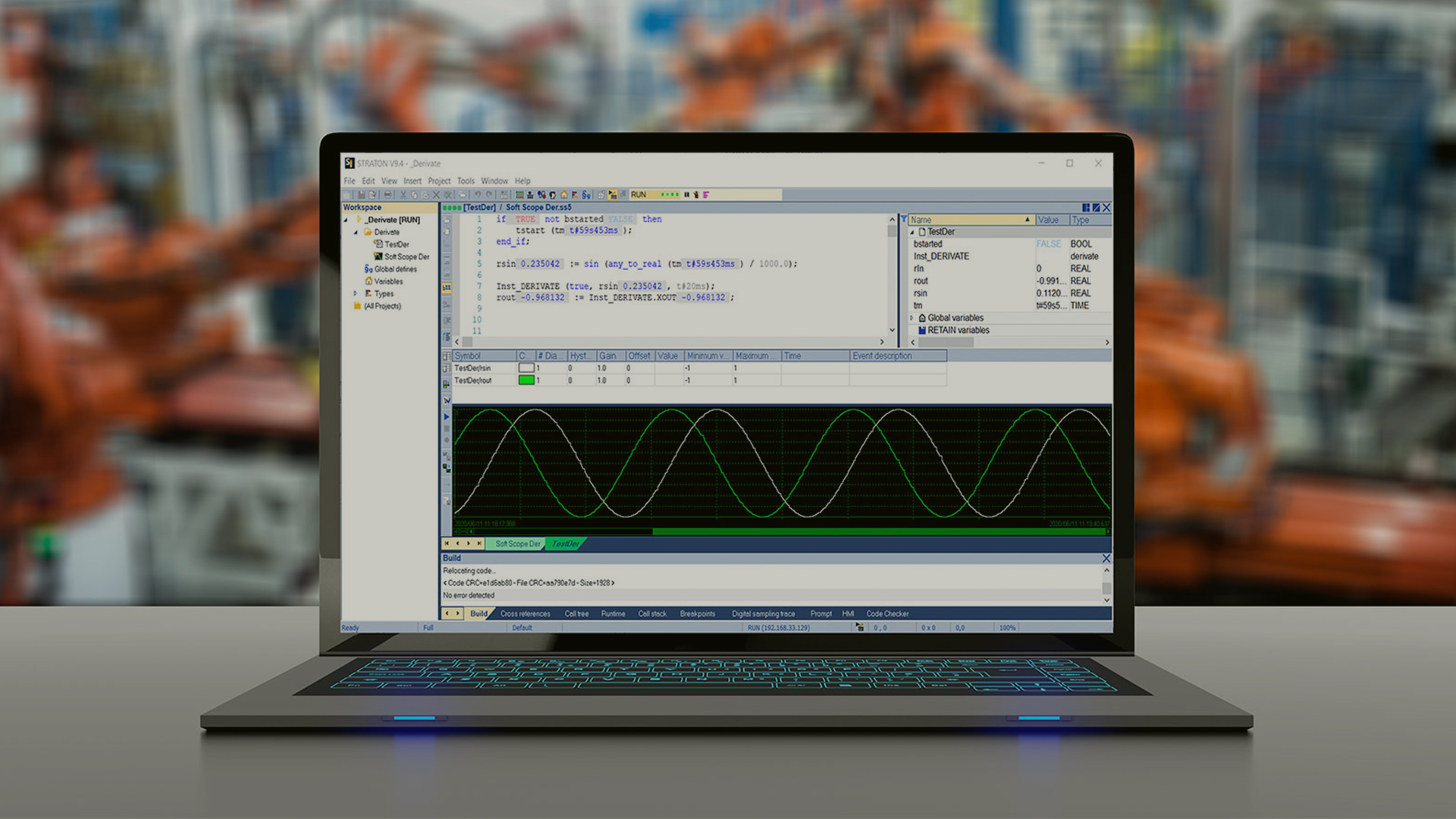

One of the results of the adoption of IEC61131 was the recognition that the software and hardware elements of programmable logic controllers could be considered separately, giving rise to the concept of Software PLC, or virtual PLC