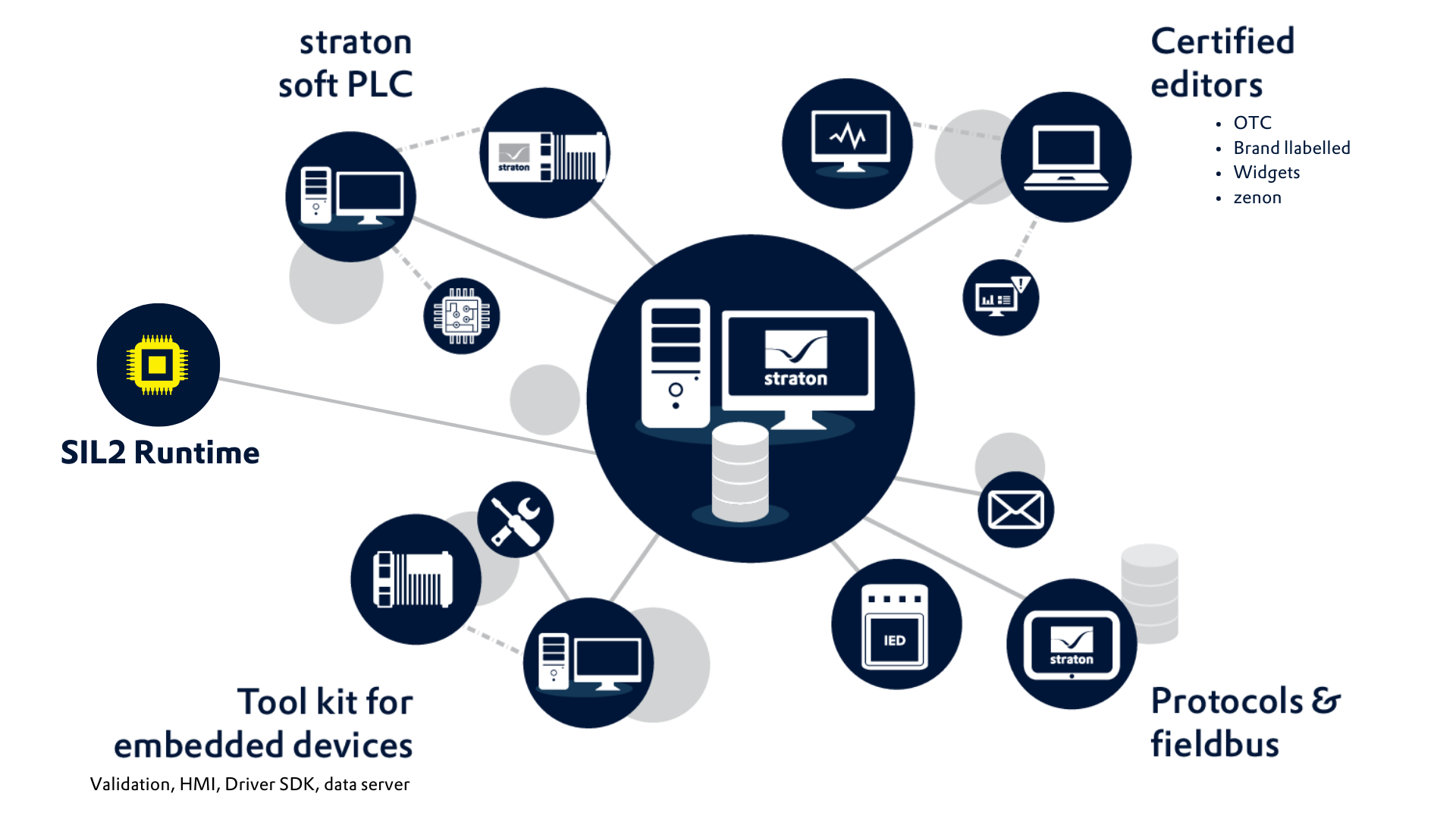

straton, software for industrial automation

A software for industrial automation

Customizing the editor

The editor represents an important part of automation applications, especially because it is used for the design and development of the application. Hardware manufacturers have to offer open, ergonomic and IEC 61131 compliant editors.

The straton development environment supports the IEC 61131-3 standard and includes all the necessary functions for an efficient and optimized programming. Online debugging, step-by-step cycles, breakpoints, graphics, oscilloscope, test sequences, change tracking, graphical comparison of project versions, configuration wizards, online import etc. An all-in-one solution for fast and optimized application development.

The hardware manufacturer can integrate additional configurators for his own I/O boards, or for fieldbuses, and any specific plug-ins or blocks. An example of a plug-in module is available for the packML.

If the manufacturer wishes it, STRATON AUTOMATION provides a solution by a development kit which allows to customize the straton editor and its specific features: branding with customized logos and name, hiding of features, customization of the help and menus…

Adding widgets in an

OEM environment

In the case of an existing development environment (Framework .Net, QT, MFC), it is possible to integrate graphical components called “controls”. Each control can be loaded and managed via a standard interface.

A large number of controls are available: from IEC 61131-3 language editors to fieldbus configurators or diagnostic tools such as the oscilloscope. An easy to use and understand solution for any OEM who wants to keep their existing user interface familiar to their users.

OEM controls integrated in the straton environment

One possibility is to create extension modules or controls and to integrate them in the straton development environment, next to the already available controls such as: IEC 61131-3 editor, configuration tools or online diagnostic tools.

STRATON AUTOMATION provides a tool to create these extension modules and to give the possibility to create programs, variables, input/output configurations automatically.

The packML is an example of a control integration made by STRATON AUTOMATION.

Tools developed to facilitate development

- IEC 61131-3 editors (ST, LD, SFC, FBD, IL)

- Spylists

- Recipe management

- Soft Scope

- Graphics

- Test sequences

- Version control with GIT or SVN

- Access to SQL databases

- Redundancy

- Project comparison

- Automation of project production

Customer cases

” The customer’s satisfaction with this application was confirmed by the level of service provided by STRATON AUTOMATION. “For us, the technical support received from STRATON AUTOMATION has been decisive. Whenever we had questions about development, we received immediate answers. In one or – at most – two days, we were always able to solve issues.”

Main needs of TRIO MOTION TECHNOLOGY to which STRATON AUTOMATION has provided solutions:

- The program developed by the user is independent of the processor.

- The programs run quickly and efficiently.

- Simple creation of function libraries for axis control.

- Programming interface seamlessly integrated into the existing Trio software to provide an integrated user environment.

- The IEC 61131-3 runtime adapts to the multitasking operating system Trio so that several languages can be executed in parallel.

“straton was very quick to learn, the programming is intuitive and the communication with various peripherals is really simple to implement. straton allowed us to create our own control algorithms avoiding the use of many devices. The creation of field blocks allows us to easily reuse pieces of programs and save precious programming hours. Depending on our applications and needs we use various hardware supporting the straton® PLC. This allows us to have a good durability in the follow-up and evolution of our machines.”

Read moreor download the trial version of straton to explore all features