LEROY AUTOMATION, a global leader and manufacturer of reliable rail automation components and on-board train control and monitoring systems (TCMS) architect, extends its software strategy with the IEC 61131-3 STRATON integrated development environment (IDE).

As the preferred automation partner for international rolling stock manufacturers and railway subsystem integrators, Leroy Automation’s engineering teams support the railway industry and its operators for new built vehicles, as well as for mid-life train overhaul or modernization projects, with innovative on-board TCMS and rail automation solutions.

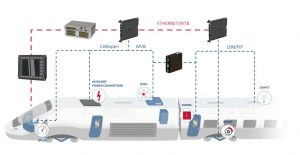

Compliant with the highest criteria of the EN 50155 standard, Leroy Automation’s advanced TCMS portfolio of solutions features high-performance, modular and extremely reliable components such as multi-purpose on-board vehicle control units (VCU), smart remote I/O modules (RIOM), and adaptable field communication gateways (SLG). Such components are programmable and configurable to meet the requirements of a wide variety of on-board train control applications: traction, energy management, HVAC, lighting, selective/emergency door, brakes, vigilance device, condition-based train monitoring…

In order to facilitate our customers’ software development and system integration tasks, Leroy Automation has decided to trust the software editor company STRATON AUTOMATION, and its straton Editor, debugging, monitoring tool chain to implement train subsystem automation projects. “Based on the optimized commercial-off-the-shelf (COTS) IEC 61131-3 STRATON software development workbench, Leroy Automation’s software application development strategy accelerates time-to-market and facilitates further enhancement software evolutions thanks to its PLCopen features”, commented Jean RUFFIE, Train System Applications Expert.

Choosing STRATON is the most appropriate choice to deploy a common software strategy across Leroy Automation’s railway products and TCMS platforms for light rail vehicles, metro cars, transit rail vehicles, high-speed rail and even passenger and freight locomotives.

The STRATON PLC automation development environment also integrates all main industrial network protocols, which are already implemented and available as a library of communication stacks for MODBUS, CAN 2.0, CANopen, J1939, EtherNet/IP, Powerlink, Profinet, SNMP, etc. In addition to the IEC 61131-3 STRATON workbench, Leroy Automation’s proprietary libraries and software drivers facilitate the integration for its TCMS product lines: RIOM and BRIO. Our programmable control units and remote I/O modules are pre-configured to address and map the end users’ I/O interfaces and communication ports to the target hardware.

User-friendly graphical interfaces are also available to set all the necessary parameters of the train-specific communication protocols such as MVB (multifunction vehicle bus) for traditional train communication networks, and even IEC 61375-2-3 TRDP (Train Real-time Data Protocol) message data for the latest train system architectures based on Ethernet train communication networks.

Thanks to such features, train system integrators and development engineers can focus on their core software algorithms and distributed process control applications using structured text (ST), ladder diagram (LD), sequential function chart (SFC), function block diagram (FBD), continuous function chart (CFC), or instruction list (IL).

In order to support train system engineers, Leroy Automation has also developed a complete train control and monitoring system (TCMS) testbed based on IEC 61131-3 STRATON software IDE. This test bench features the main hardware components of TCMS architectures: vehicle control units (VCU), remote I/O modules (RIOM), and driver display units, which are all interconnected using MVB nodes, fast Ethernet integrated train backbone nodes and multi-port Ethernet consist switches. Delivered with software application notes and STRATON project samples, integration engineers keep full control to lead train innovation thanks to interoperable hardware and independent software solutions.

For more information, visit www.LEROY-AUTOMATION.com

About LEROY AUTOMATION

LEROY AUTOMATION is a company headquartered in Toulouse with a North American subsidiary located in Montreal. For nearly 40 years, LEROY AUTOMATION has been designing, manufacturing and marketing automation products and embedded electronic equipment for on-board rolling stock vehicles, automation solutions for electrification networks, and railway control systems. Especially designed for harsh conditions, the company’s products are suited for demanding electromagnetic and extreme thermal, as well as for high vibration operating environments. From feasibility studies, detailed engineering and design, to maintenance and repair services, LEROY AUTOMATION collaborates with its worldwide customers during the complete life cycle of their products and systems. For several decades, LEROY AUTOMATION has cooperated with ALSTOM, BOMBARDIER, CRRC, SIEMENS, THALES, and others in international project and product developments along with railway and mass transit authorities, industrial and military customers, system integrators and OEMs worldwide.

31/07/2020

Comments are closed.